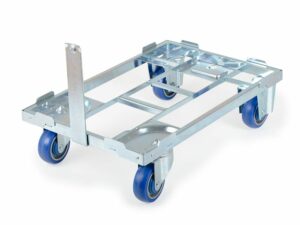

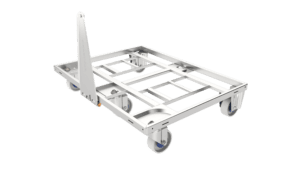

For the automotive industry, lean manufacturing means making sure that the right component quantities get to the right place at the right time. Whether you are an OEM or a sub-supplier, changing from pallets to wheels is the most important decision when deploying lean logistics.

Ensuring more efficient, forklift-free internal logistics can cut the costs of inventory, handling and in-house transportation. Increased efficiency also means space optimization, shorter turnaround times and better health & safety for staff. Smooth in-house logistics will fully support Lean production principles.

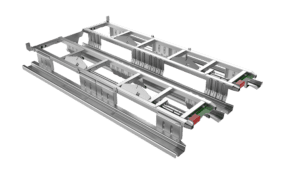

Standardized integrated transport systems improve delivery efficiency and precision, creating an optimized supply chain.