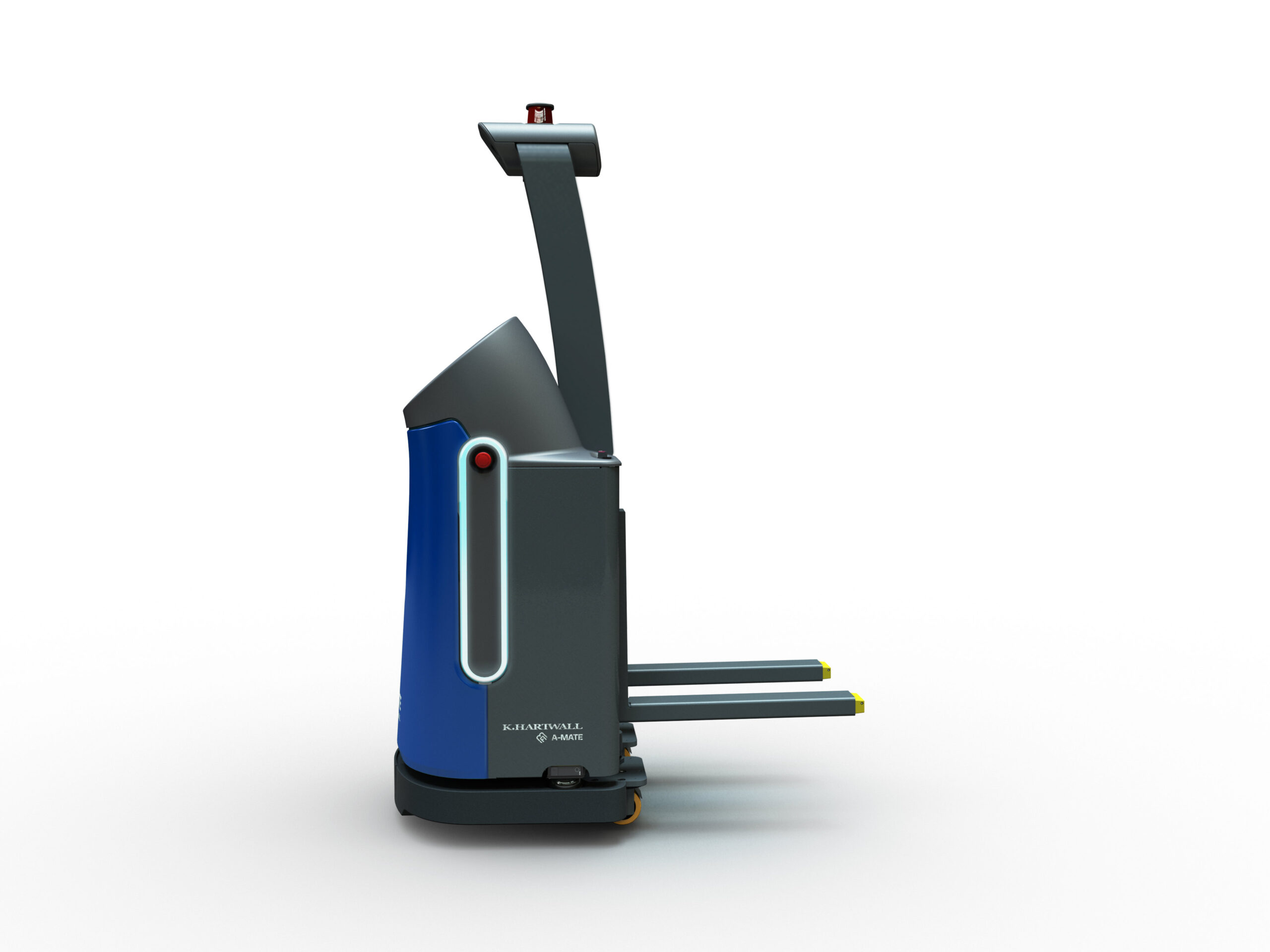

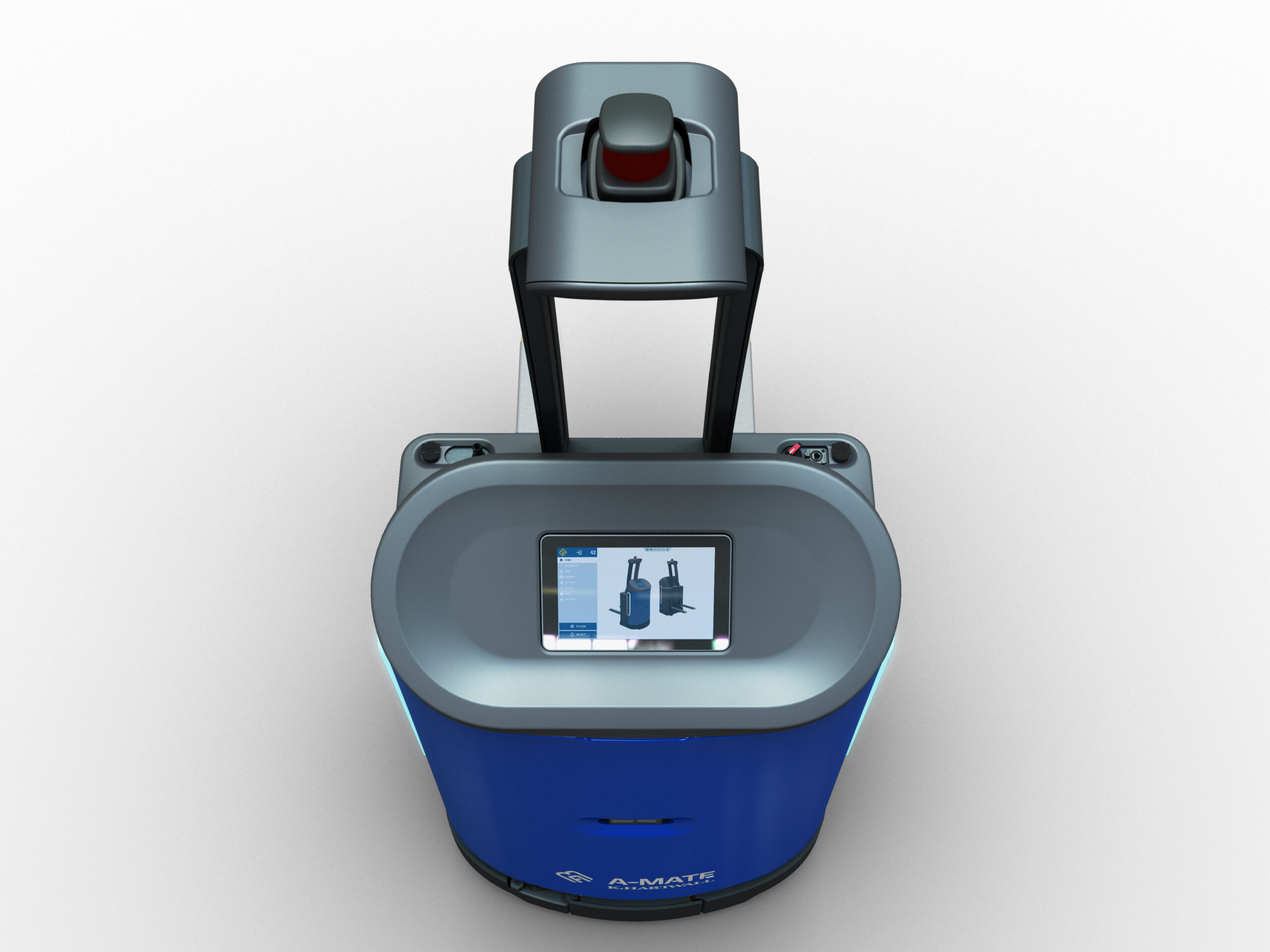

A-MATE® Lite

A-MATE® Lite is the first counterbalanced and fully electric mobile robot in its class

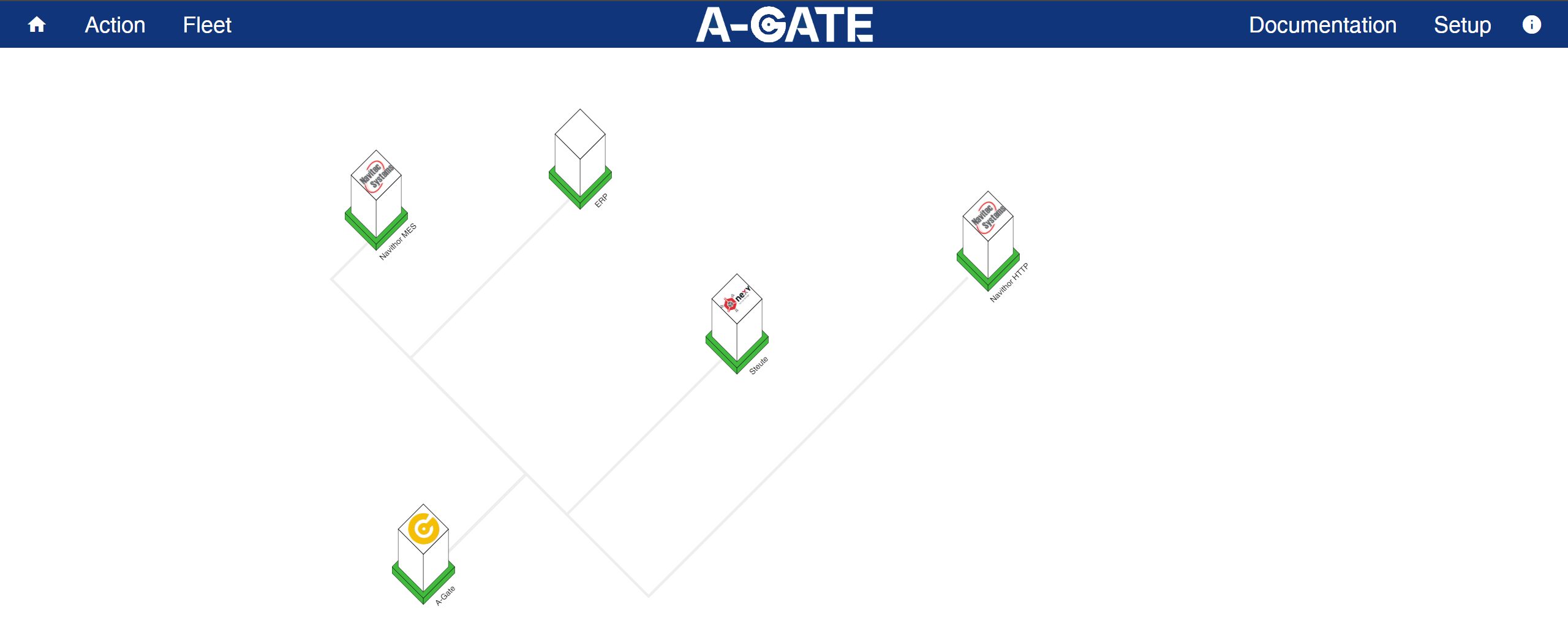

It is designed to transport pallets, dollies and roll containers in production and logistics environments like warehouses and sorting centres. With its customized fork concept it can also transport customer-specific load carriers. The innovative slim design combined with the omnidirectional driving concept make it ideal for the automated load carrier transport in confined spaces.

✓ Innovative and compact design

✓ Omnidirectional driving system

✓ Powerful electric free lift and counterweight

✓ Customized fork concept

✓ 360° safety

✓ 3D load carrier detection