Intralogistics is undergoing rapid change. The focus is on automation and digitalisation to make processes more efficient and flexible. The A-MATE® product family from K.Hartwall supports numerous customers in making the transition to automated intralogistics processes. Another important step is the integration of innovative and dynamic load carrier detection with the help of 3D cameras.

Basic functionality of 3D load carrier detection

A 3D camera is used to scan the environment in three-dimensional space, allowing a wide variety of load carriers to be precisely localised and identified in their surroundings and their position and orientation to be determined. This is done in several steps, with simulation, sensor technology, image processing and algorithms for 3D object recognition playing a central role:

- Simulation: Before the customised load carrier is tested in a real environment, K.Hartwall first carries out a simulation. Here, the basic technical feasibility is checked on the basis of 3D data of the load carrier, which significantly reduces the subsequent effort required for production tests.

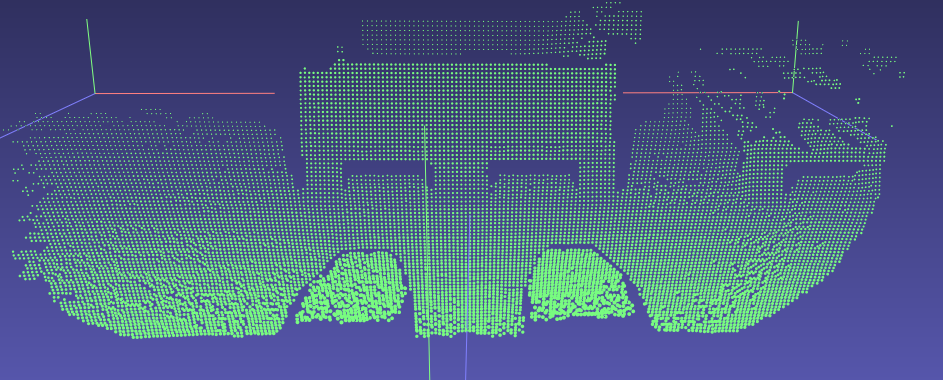

- Sensors: Once the simulation has been successfully completed, sensors capture a three-dimensional point cloud of the real environment. In the case of the A-MATE®, this is a time-of-flight camera with infrared, which delivers high accuracy and high-resolution, true-to-the-original depth information.

Point cloud of the 3D camera - Data preprocessing: The point cloud is first cleansed to reduce noise and retain only relevant areas, and the environment is then segmented to isolate the charge carrier as an independent object.

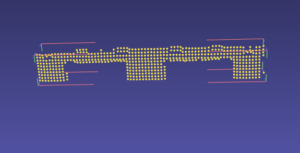

Point cloud of the load carrier (i.e. pallet) after successful clean-up - Object recognition: Characteristic features of the charge carrier such as structure, dimensions and other features are identified with the help of specially developed algorithms.

- Position and location determination: The position (x, y, z) and orientation (roll, pitch, yaw) of the load carrier are calculated relative to the A-MATE® and translated into the coordinate system. Currently, K.Hartwall is still focussing on the detection of load carriers on the floor with a maximum deviation of 20 degrees from the original position. Pallets can be placed next to each other with a minimum distance of 10 cm.

- Decision-making and navigation: The navigation route of the A-MATE® is planned based on the recognised position and orientation of the load carrier. Omnidirectionally driven AMRs such as the A-MATE® FreeLift or A-MATE® Lite can implement corrective manoeuvres in the tightest of spaces to finally successfully pick up the load carrier, which is offset in relation to its origin.

Numerous advantages for the end customer

“The integration of 3D load carrier detection within our A-MATE® product family brings numerous advantages for the user,” says Dhaval Patel, software developer and expert for image processing systems at K.Hartwall. One example is that the ability to recognise a wide variety of load carriers leads to “an increase in flexibility within the intralogistics process of our end customers, as the positions of load carriers are no longer fixed, but can also vary within the specified tolerances,” continues Patel. This results in time and cost savings for the end customer, as there is no need for additional investment in infrastructural measures such as positioning aids or costly training to sensitise employees to the correct positioning of the load carrier.

“3D load carrier detection offers our customers real added value and plays a decisive role within the overall architecture of our A-MATE® product family in order to take our customers‘ intralogistics processes to a new level,” concludes Patel.