Here, we delve into the 5 current trends shaping the future of automation, focusing on labour shortage, interoperability, safety, IT and OT security, and the innovative concept of Plug, Connect & Produce.

Labour Shortage: A Catalyst for Automation

One of the most pressing issues facing industries worldwide is the labour shortage. As the workforce ages and fewer younger individuals enter manufacturing and logistics roles, companies are struggling to maintain productivity levels. This shortage is particularly acute in sectors like warehousing, where the demand for workers has surged due to the rise in e-commerce.

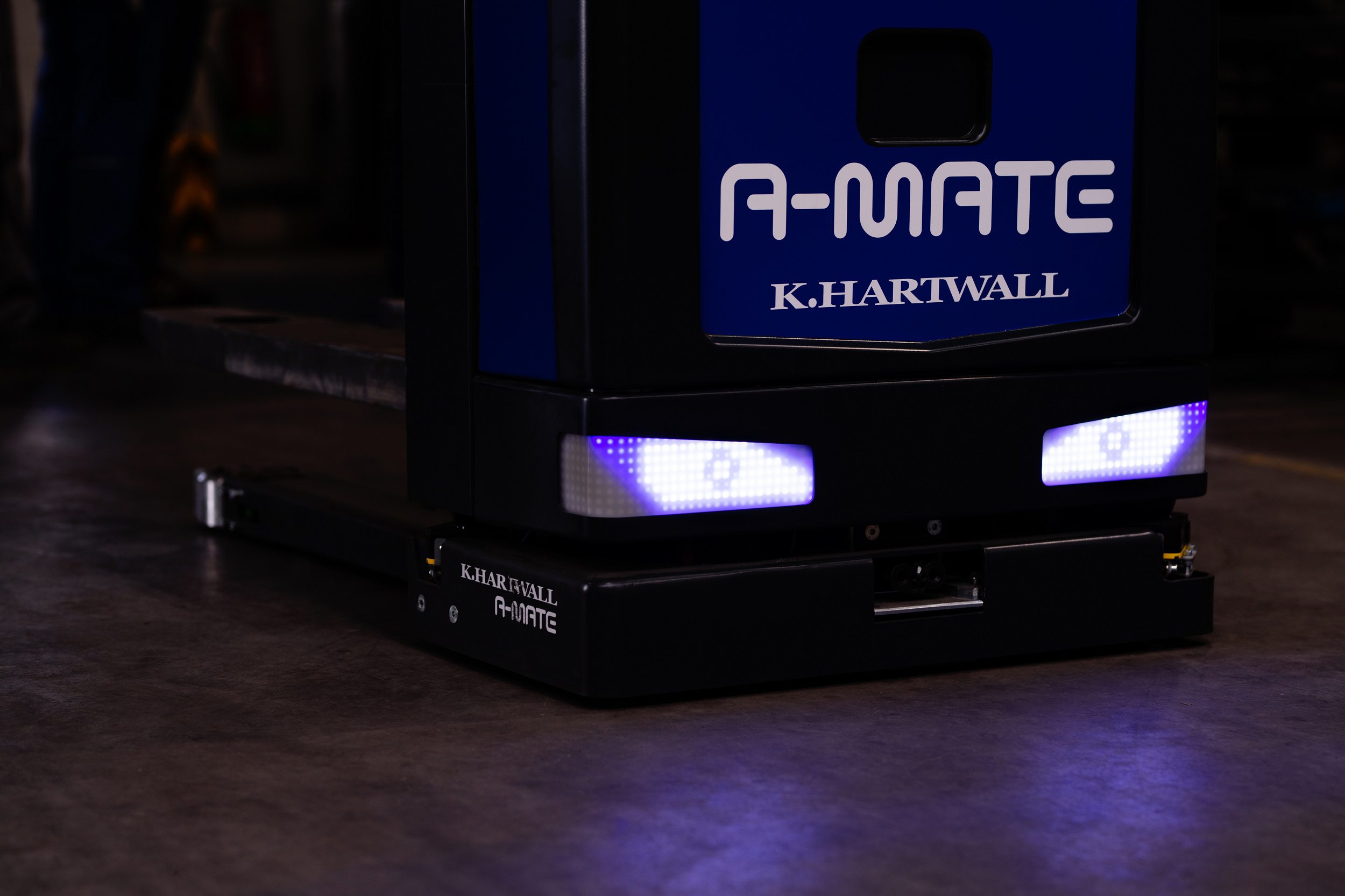

What can companies do to address the labour shortage? Consider solutions like Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). By automating repetitive tasks, these robots can fill the gaps left by a shrinking workforce. Not only do they enhance productivity, but they also allow human workers to focus on more complex and value-added activities. This synergy between human and machine is crucial for maintaining competitiveness in today’s fast-paced market.

Interoperability: Bridging the Automation Ecosystem

Interoperability is another key trend driving the next generation of automation solutions. In a diverse technological landscape, the ability of different systems and devices to work seamlessly together is paramount. When considering automation solutions, it is recommended to look for those that can easily integrate with existing infrastructure and other automated systems, like certain AGVs and AMRs for example.

Keeping interoperability in mind, will allow the focus to be on solutions that are not only future-proof, but also scalable. This approach reduces the complexity and cost associated with upgrading or expanding automation capabilities, making it easier for companies to adapt to changing demands and technologies.

Safety: Ensuring a Secure and Productive Environment

Safety is a top priority in any industrial setting, and the integration of AGVs and AMRs introduces new considerations for maintaining a secure environment. Choosing automation solutions that are designed with safety in mind and have advanced safety features will help protect both human workers and other machinery.

Some of these safety features, specifically for AGVs and AMRs, could include sophisticated sensors and algorithms that enable these mobile robots to navigate complex environments, detect obstacles, and avoid collisions. Additionally, look for solutions that abide by industry standards and regulations, ensuring that these solutions are safe and reliable.

IT and OT Security: Protecting Critical Infrastructure

As automation technology becomes more advanced, the lines between Information Technology (IT) and Operational Technology (OT) continue to blur. This convergence brings about new security challenges that must be addressed to protect critical infrastructure from cyber threats.

Ideally, choosing an automation solution designed with secure communication protocols and encryption will safeguard data integrity and unauthorized access. This will also help create a sense of confidence, knowing that internal operations are protected from potential cyberattacks.

Plug, Connect & Produce: Simplifying Automation Deployment

In today’s fast-paced industrial environment, the ability to quickly deploy and scale automation solutions is a significant advantage. The Plug, Connect, and Produce approach allows companies to easily implement AGVs and AMRs into their existing workflows without the need for extensive reconfiguration or customization. The result is a seamless transition to automated operations, enabling businesses to reap the benefits of increased efficiency and productivity almost immediately.

Recap

The landscape of industrial automation is rapidly evolving, driven by trends such as labour shortages, interoperability, safety, IT and OT security, and the need for quick and easy deployment. As a leader in AGV and AMR manufacturing, K.Hartwall is at the cutting edge of these developments, providing innovative solutions that help businesses navigate the complexities of modern automation, not only for today, but for the future of tomorrow.

For any questions, please reach out to Aaron Zimmerer at [email protected].

Aaron Zimmerer,

AGV Product Owner