The most compact counterbalanced AGV

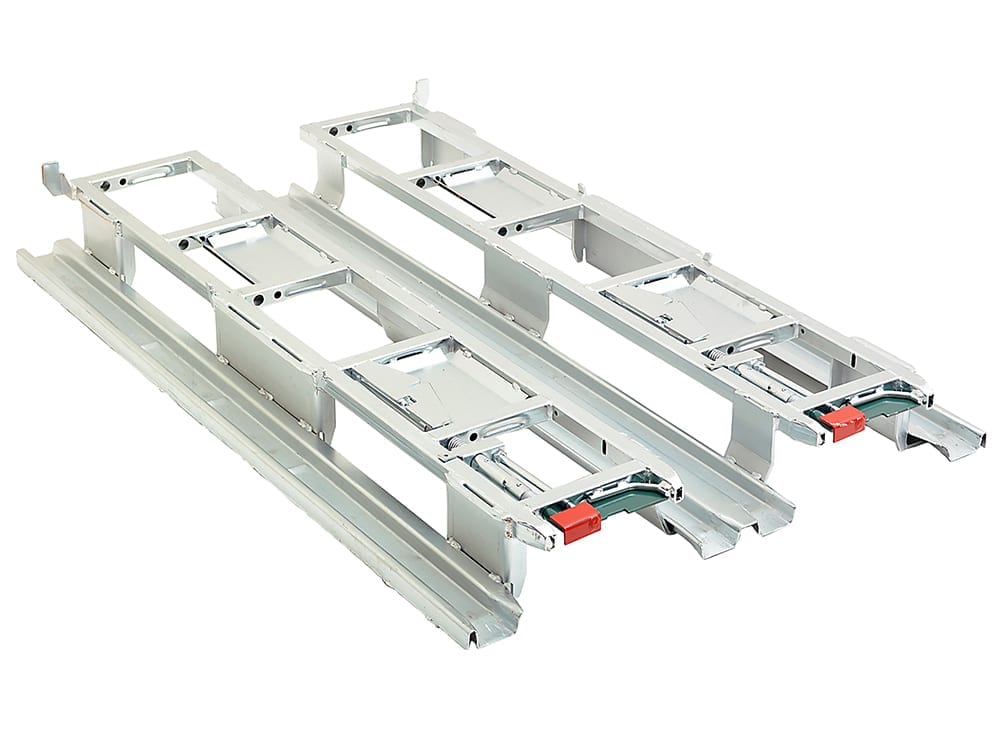

A-MATE® Counter

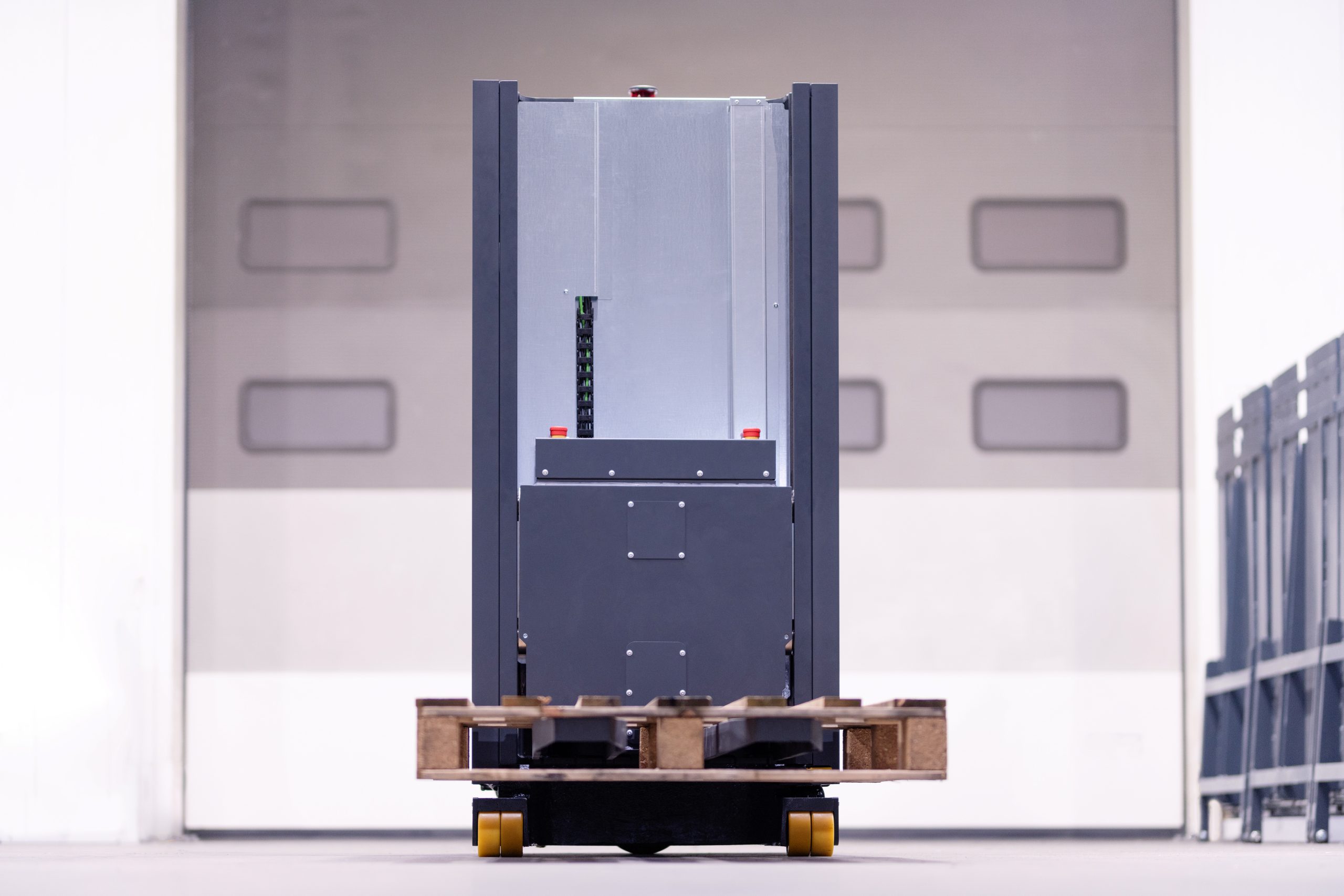

With the newest addition to the A-MATE® product family, users benefit from a fully electric mobile robot that has cantilevered forks and counterweight to move various load carriers like pallets or lattice boxes.

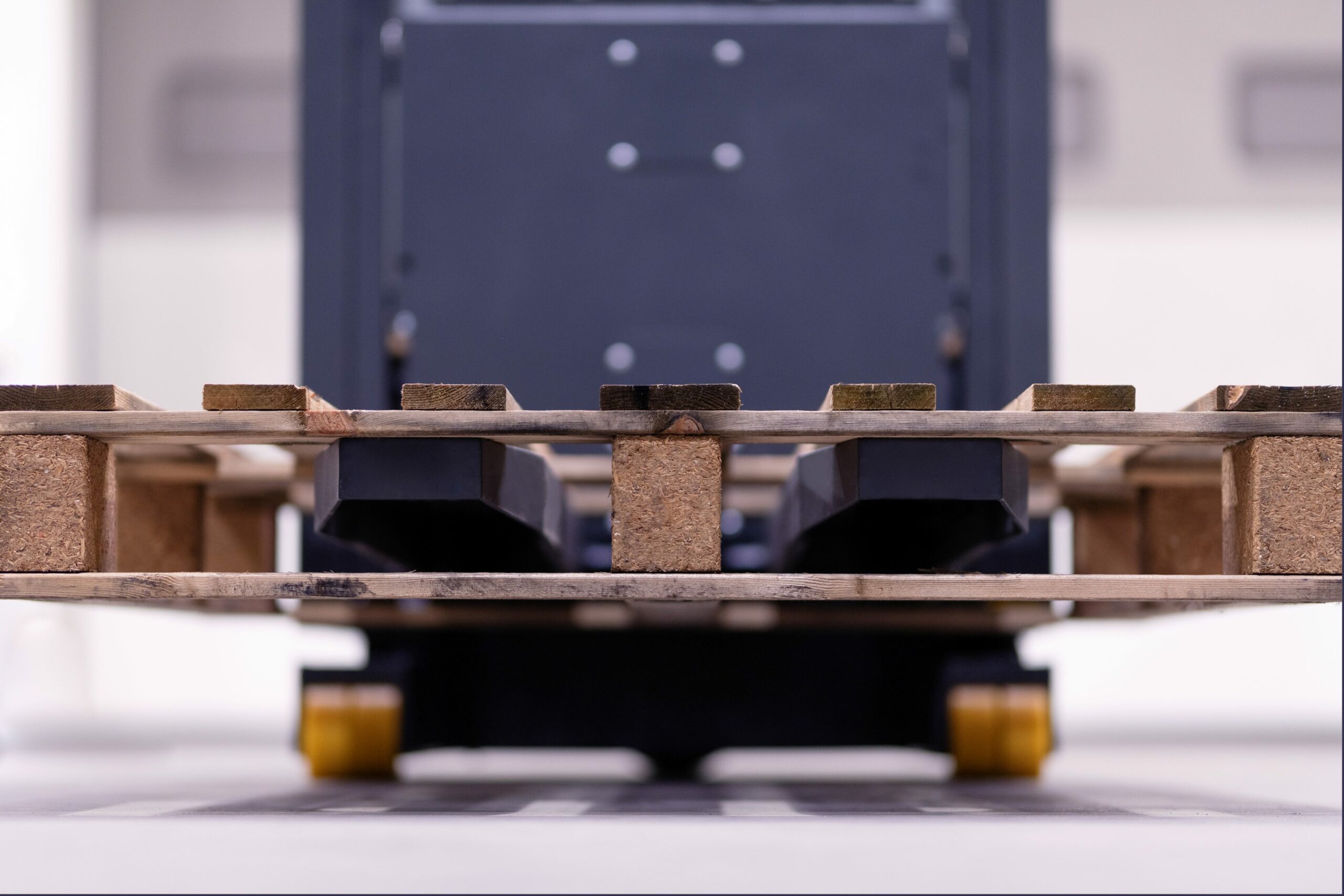

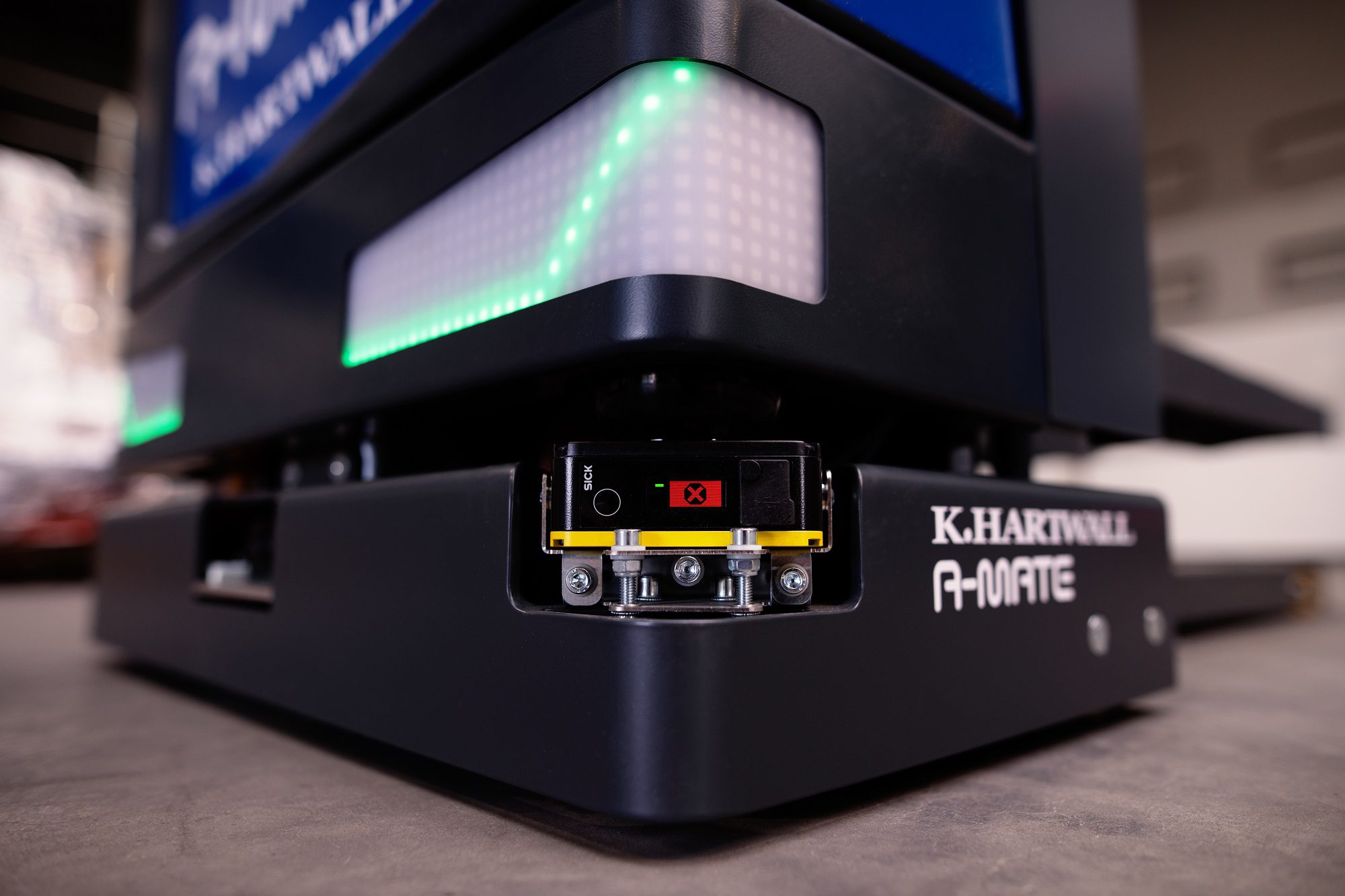

✓ Compact design

✓ Bidirectional drive

✓ Powerful electric free lift

✓ Customized load handling devices

✓ Pallet detection

✓ Minimal maintenance costs