PostNord is the leading logistics provider in the Nordics with almost 4 billion euros turnover and over 24,000 employees. In Finland, PostNord operates since 2013 and is one of the biggest parcel carriers with over 2,400 pickup points and 12 million parcels delivered annually.

PostNord’s overall climate target is fossil-free transportation and operations by 2030.

In Finland reducing the carbon dioxide emissions of line haul transport is a significant factor and the goal set by PostNord is to cut 40 percent of its carbon dioxide emissions by the end of 2025 from the level of 2020. By streamlining and optimizing line haul transports, PostNord aims to ensure that its fleet of trucks transports full loads with as few driving kilometers as possible.

“In 2023, approximately 48 percent of PostNord’s transport carbon dioxide emissions were caused by line haul transport. This year, the corresponding number has dropped to 42 percent. In addition to lower emission fuels, various transport efficiency measures like implementing K.Hartwall’s cages have enabled positive development and reduction of carbon dioxide emissions”, comments PostNord’s Chief Operating Officer Jussi Broberg.

The challenge and solution

Prior to 2022, PostNord primarily relied on mixed pallets for their internal line haul transportation between terminals. This approach presented challenges, including suboptimal truck utilization and concerns regarding worker safety and ergonomics.

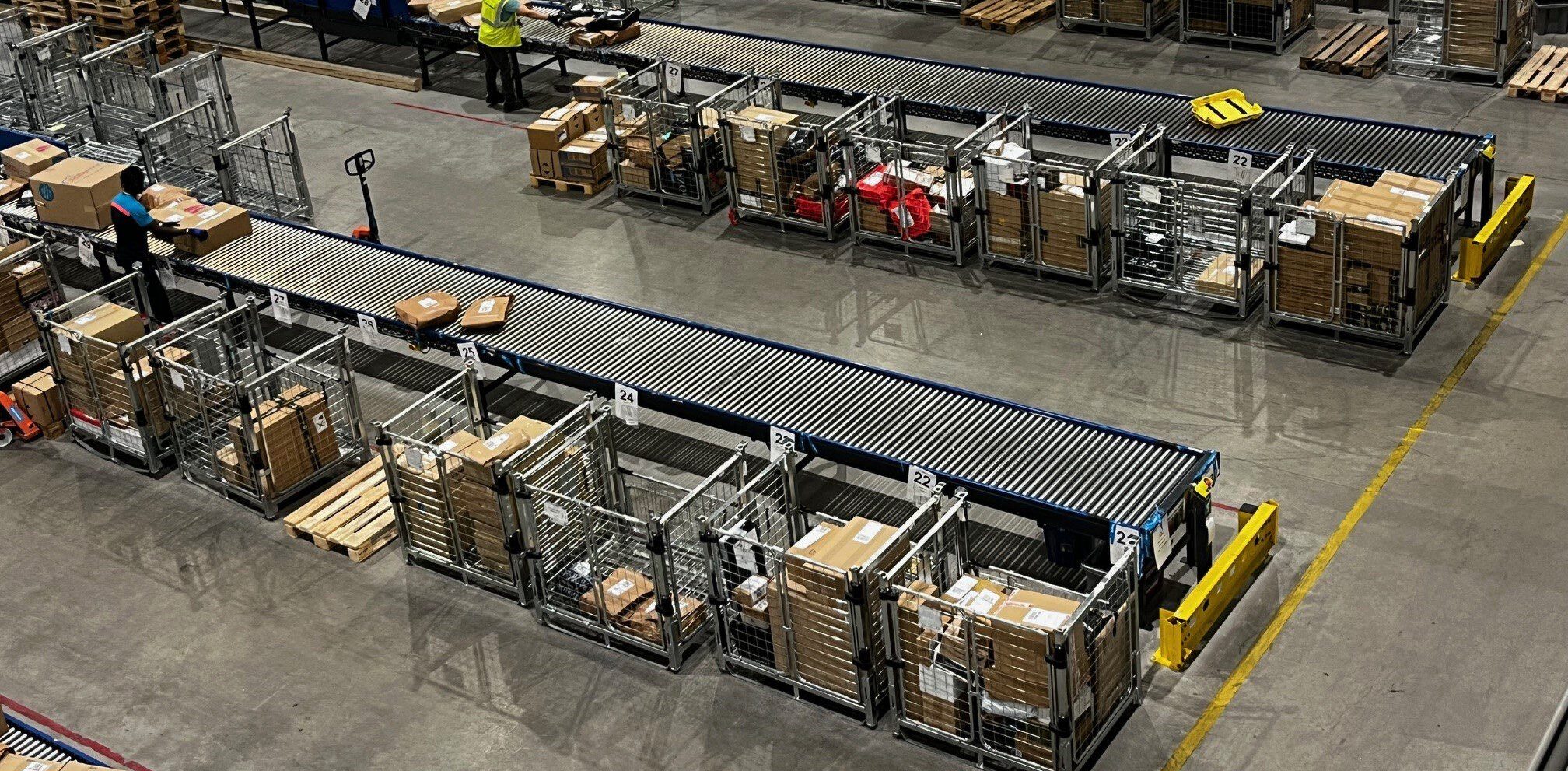

Line haul transport efficiency depends on maximizing truck fill rates. In practice, this means more compact truck loading enabled by innovative transport cage solutions. K.Hartwall has supplied PostNord with ca. 2,000 ISO size SmartCube cages. The foldable & stackable cages are filled at terminals, then stacked on top of each other and finally loaded onto the truck. During the last two years, PostNord has invested heavily in new types of transport cages for trucks. The cages enable cargo to be loaded in two layers, increasing the fill rate of the trucks considerably. Cages are fully foldable enabling efficient storage and handling of empty units.

Improving line haul transport efficiency is also tied to the cargo being transported. Today, PostNord transports a growing share of e-commerce parcels for consumers. More standardized cargo enables more compact loading. “With the current focus, we have been able to increase the fill rate of our line haul transport by an average of 30 percent compared to a few years back,” adds Broberg.

“It has been great to see how PostNord has improved their operational efficiency with our cages. Our collaboration has been smooth from the start and the general feedback regarding the quality and usability of the cages has been overwhelmingly positive”, acknowledges Mikko Rissanen, KAM Finland and Baltics at K.Hartwall.

“We have been very pleased with the quality of the cages and the benefits they have brought to our overall efficiency in operations. They are a sustainable and long-term solution that will help us to reach our sustainability goals.” praises Broberg.

K.Hartwall SmartCube®

- Foldable and stackable metal cages

- Compatible with pallet-based material handling equipment

- Load capacity 1,000 kg

- Modular sizes available for different material flows

- 3:1 folding efficiency ratio when empty

For more information about the SmartCube® foldable cages, please check our website: https://k-hartwall.com/products/foldable-cages.

Mikko Rissanen

Key Account Manager, Finland and Baltics

[email protected]